About Us

About The Company

We are building up the most efficient industrial heating system. Using Microwave. We are in the path of displacing steam boilers, heating coils, hot oil baths. Our heating system is going to be in every Waste Management system, Agriculture industry, Food industry and Chemical reactors. We are building“MUMAH”

Vision

Our vision is to create world class, efficient microwave drying systems that gladly engages secondary agricultural producers and wet waste managers.

Mission

We are on a mission to save food, using energy efficient & affordable microwave-based rapid drying systems, for creating value added products in secondary agriculture and bio-degradable waste management. We shall achieve this with passionate and focused teamwork, constant innovation, sustainable models, and effective community participation.

Values

Passionate

Enviro conscious

Learning

Integrity

Caring

Aspiring

Novel

About The Team

Dr.Priya Rao

- A Practical Teacher Cum Scientist Who, As An Entrepreneur, Developed A Successful R & D Wing Of A Biotech Industry With A Die-Hard Obsession To Create Wealth From Waste.

- Focuses Only On Product & Process / Technology Development Related To Agri- Biotech, Enviro-Biotech, Waste Management, Natural Products, And Biopolymers.

- Passionate About Sustainable Lifestyle Protocols.

Credentials:

- Co-Author Of ELEVEN International Patents

- Published And Presented Many International / National Papers / Articles.

- Two-Time DST-Woman Scientist Awardee

- Founder/ MD Of Pelican Thermogenics Pvt Ltd, A Start Up Company in Kerala.

- Head Of R & D - Awarded the National Level DBT- BIRAC INNOVATION AWARD For 2012, For Green Industrial Processes.

- Secretary Of Pelican Foundation - Work with Student Community to Promote Green Lifestyles. Received The National Award-NPC 3R Award for Mission Zero Waste In 2018

- Expertise In Industrial R & D Training Programs

- Awardee Of Various Govt. Of India Projects as Part Of DSIR Recognized R And D Unit.

- Visiting Faculty for The Programs Conducted by Karnataka Biotech Finishing School

- Academic Council Member For A Few Academic Institutions

- Expertise In Intellectual Property Rights & Statutory Compliances

- External Expert for Academic Auditing in Colleges

- Experience As Teacher at The UG & PG Programs In Phytochemistry, Organic, Biochemistry, Diagnostic And Industrial Chemistry.

- Experienced In Organizing Social Level Programs Related to Waste Management And Promotion Of Sustainable Green Lifestyles.

Dr. C.N.Manoj

About

Holds a PhD in Natural Products chemistry from Gandhigram Rural University, Tamil Nadu, India.

After 3 years as Research Scientist and Technical Director in couple of Phyto-pharma industries, founded PBCL as a sustainable and socially responsible enterprise with intent to protect the environment.

Have since created a number of programs and projects in Kerala, Karnataka, Tamil Nadu, New Delhi for promoting sustainable lifestyle and eco-friendly practices.

Innovation

An Innovator, with Gandhian thoughts and business development capabilities, sustainable business model on socio-commercial theme "of Creating wealth from waste" is the primary focus. Projects that create value-added products from wastes, extension by creating awareness among the younger generation towards urban waste management protocols are the major thrust areas.

Ongoing research projects with various Govt. of India organizations like DBT, DST, DRDO and a few other projects are in pipeline with Govt. and private research organizations.

- Despite the strong roots in Chemistry, is a staunch follower of Biotechnology and finds it as the future - not only for business but also for sustenance of mother earth.

- All the calls to profession, hobby, passion, and leisure have one answer – environment.

- Believes in the art of blending technology, commerce, and marketing into socio-environment objectives

Recognitions

- Co-author: 20 research papers & 11 patents

- Recipient of the Best Entrepreneur award - from the Ministry of Industries, Govt of Kerala, awarded in March 2010.

- Awarded the National level DBT- BIRAC INNOVATION AWARD for 2012, towards innovative products, such as the organic composting agent for solid waste management.

- Joint executive coordinator in National Games 2015 to execute green protocol

- State Resource Person, Suchitwa Mission.

- Convener, My Clean Malleshwaram, Bangalore to implement waste management protocols.

- Founder, Ente Bhoomi Lifestyle store. Association.

- Trustee, Pelican Foundation

- Managing Director, Pelican Biotech & Chemical Labs P Ltd.

- Director, Pelican Thermogenics P Ltd

- Director, Pelican Kenterra P Ltd

- Founder, Cpowe5, Change can change climate change, Mentored By Trivandrum District collector

- Member, Governing body, National Coir research and Management Institute, GOK

- Member, State level committee for plastic waste management.

Innovation and Product

Microwave Heating

Microwaves are electromagnetic wave that can be used for rapid heat transfer that enable volumetric and selective heating. Microwave further supplement by providing for compactness of equipment, speed of switching on and off and pollution-free environment as there are no products of combustion.

Advantages of Microwave Heating

The main features of microwave heating are:

- It heats the matrix and not the container, thereby heat loss is considerably reduced.

- The nutrients in dehydrated food is not hugely altered by microwave under vacuum.

- One of the most efficient and proven heating technologies in terms of reaction time and energy consumption.

The Solution

Multiple Magnetron Heater 'MuMaH'

Novel Multiple Magnetron Microwave Heating Element

Multiple Magnetron Heater “MuMaH” is plug and play solution for heating and drying requirements. MuMaH house several low capacity magnetrons arranged in a specific way to prevent wave interference and selective and precise heating.

The system can be used to dehydrate products such as vegetables, fish, fruits, meat, chemicals etc. This technology of dehydration can revolutionize the food industry wherein dehydrated food products are similar to that generated out of freeze drier with shelf life at ambient temperatures.

Advantages of MuMaH

- In MuMaH we use multiple magnetrons of low capacity like 1 /2 KW. This overcome the high cost of high capacity magnetrons (eg: 5, 10, 20 KW etc) and accessories such as huge transformers. The cost is reduced to the extent of around one-tenth to one-twentieth.

- Dehydrated products being lighter will considerably reduce the cost of transport and will have exponentially increased shelf life.

- The dehydration process can be maneuvered to generate fat-free, pesticide-free and antibiotic-free food products.

Microwave heating system using low capacity multiple magnetrons in a single chamber with vacuum

- Use of vacuum enhances efficiency and enables use of solvent.

- Use of process control systems enables local area heating control – prevents over-heating and charring.

- Microwave now scalable to many 1000’s of Litres.

Our Achievements

• Incubated at IIM Kozhikode under La Eve Women Entrepreneur Incubation Program.

Pelican Thermogenics was incubated into La eve women entrepreneur incubation program which is flagship event of IIMK’s LIVE program in March 2021

https://www.iimklive.org/live-wires

• Incubated at KAU RABI PACE 2020:

Pelican Thermogenics was the part of an incubation program organised by the Kerala Agriculture University, Thrissur for 8 Weeks (August - September 2020). We incubated at KAU under the RABI PACE 2020

• Finalist in FLCTD Accelerator Program:

We were a part of the FLCTD Accelerator Program and reached the final Top 8 Companies

• Associated with Kerala Startup Mission

We are active partners with KSUM as part of their Innovation Grant 2020

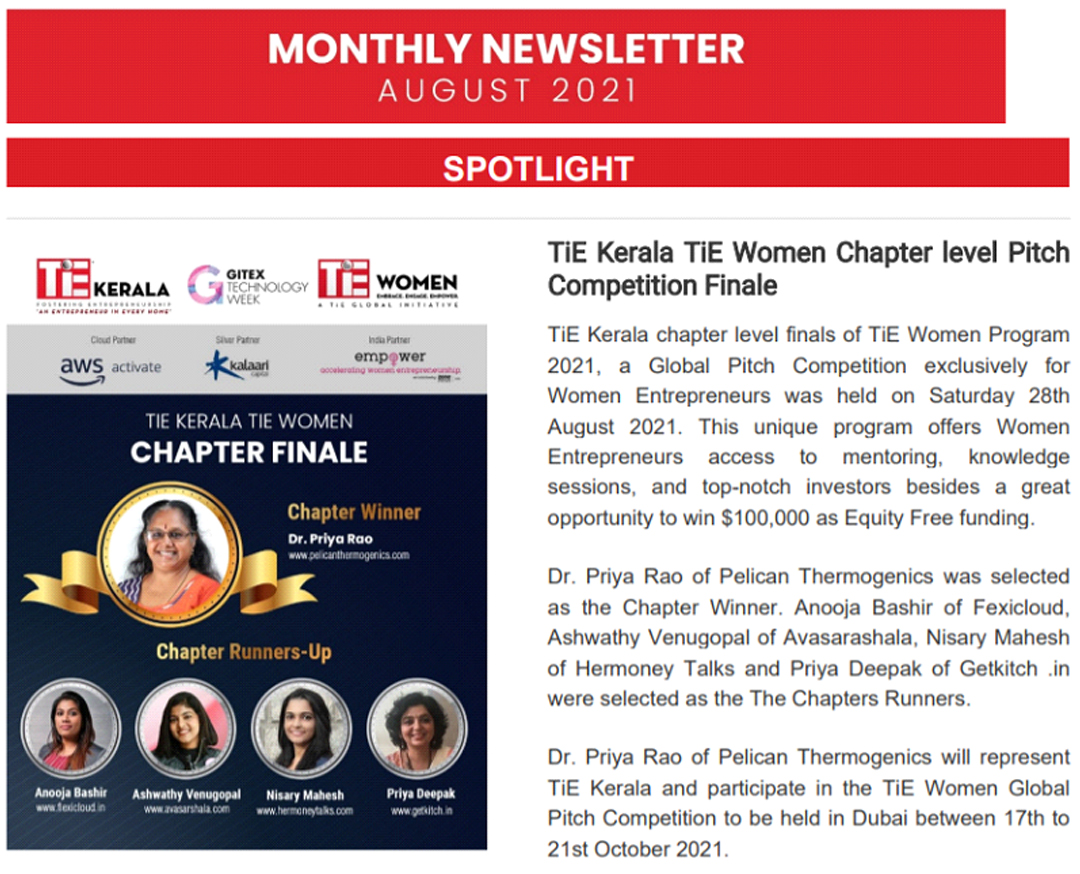

• Winner of TIE Women Kerala Chapter

• Participant in Acceleration Program 2021 By Global Parli & AIC-RMP

https://www.agrigateindia.in/shortlisted-startups/

• Cohort Of Womenpreneur 2021 By Atal Incubation Centre Jaipur, India

• Participant in I- RISE Program 2021 Organised By IISER Mohali, Punjab

Selected into I- RISE Technology Business Incubation By IISER.